簡介:多分支井技術,對于氣藏開發來說,具有非常有價值的作用。多分支井完井能夠保證長期的產能增量。

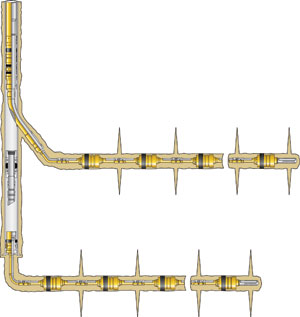

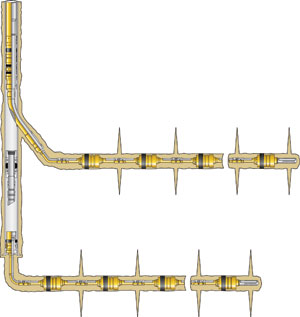

This multilateral completion uses five-stage openhole packer systems.

Although multilateral (ML) well technology is often thought of as a tool primarily for offshore use to capture outlying pockets of hydrocarbons, the majority of the installations have actually been on land in low-cost environments. Applying this technology has shown many benefits, but only in a few cases is ML technology used as the main field development technique. However, as operators look at lowering field development costs while increasing production, they are turning to ML wells as the solution.

ML completions provide excellent opportunities in unconventional gas developments. Two or more laterals off of a single vertical well bore can result in considerable cost savings and increased production. However, for maximum benefits, production from two or more laterals has to match or exceed the rates expected of the same number of vertical wells. And the design has to incorporate the ability to selectively re-enter and stimulate stages in each wellbore in order to enhance overall hydrocarbon recovery.

In April 2000, Baker Hughes deployed the first Level 6 ML stackable splitter system designed for fracturing gas wells. This system had 5.5-in. tubing/casing looking up with two 5.5-in. legs looking down. In this application, two of these systems were stacked so that there were three lateral well bores. To run into the well, it had to drift through 133⁄8-in. casing and be cemented in 121⁄4-in. open hole. It provided selective access and selective stimulation to all laterals up to 7,500 psi pressure differentials. At the time, the procedure lacked the commercial viability to become a mainstream field development technique; however, multilateral technology has continued to advance so that simple and reliable high-pressure junctions can now be applied in low-cost environments.

Recently, an operator of an unconventional gas play put the technology to the test. The challenges for the ML wells in the Granite Wash reservoir in the Texas Panhandle were:

• Full opening 41⁄2-in., 3.875-in. drift production in both laterals;

• Sealed isolated junction that could withstand 10,000-psi fracturing treatments (TAML level 4 junction);

• Mechanical integrity across the junction to support the formation;

• Capabilities for re-entry and restimulation of both laterals at a future date;

• Lower cost as compared to two single wells; and

• Positive production results.

The HOOK Hanger (in blue) is latched into the key seat of a window cut in the casing. (Figures courtesy of Baker Hughes)

Baker Oil Tools Frac-HOOK and Frac-Point systems were chosen for the task as these systems do not require many additional trips to install. The Frac-HOOK ML casing fracturing system comprises a HOOK Hanger ML junction that provides mechanical support at the junction window and re-entry capabilities to all laterals. It has an extensive history of being used in TAML Level 3-5 completions at inclinations ranging from 0° to 90° and at junction depths at more than 14,000 ft (4,270 m). To obtain a high-pressure seal at the junction, a ZXP liner top packer is used as an integral part of the HOOK Hanger. Lateral and mainbore diverters are used to selectively fracture the formation as well as for future re-entry capabilities.

The system provides for one-trip deployment: The HOOK Hanger, with a lateral drilling diverter or lateral re-entry diverter pre-installed, is run as part of the lateral liner installation. Either of these diverters allows setting of bridge plugs and for perforating and fracing below the hanger in the lateral while maintaining pressure integrity across the hanger window. The mainbore fracing diverter allows similar functionality, but for the main bore. These diverters can be deployed with threaded pipe, coiled tubing, or a snubbing unit.

The Frac-Point system (liner top packer, openhole packers, frac sleeves, wellbore isolation valve, and pressure-actuated sleeves) allows completion of the well without cementing and perforating in the producing interval. Openhole packers provide isolation along the length of the liner, eliminating the need to cement the liner in the lateral section and increasing formation interface. They also eliminate the need for perforating because sleeves provide access to the zone of completion for both fracturing and production. Fracture treatments for each section can be pumped on the same day, eliminating the expense of mobilization and demobilization of pumping equipment. The system provides better fracture extension control than nonselective hydraulic fracturing, resulting in improved initial productivity and accelerated reservoir drainage.

The basic installation process for the well was:

• Drill main bore;

• Run Frac Point completion system in the mainbore lateral;

• Set whipstock above the lower completion, sidetrack the well, and drill the upper lateral;

• Retrieve whipstock from the well;

• Make up the upper system below the HOOK Hanger and run everything into the well, landing the hanger in the window;

• Fracture the lower lateral;

• Fracture the upper lateral; and

• Achieve commingled flow.

The design for the openhole packer system would use the following sizing:

Use Hole Size Casing Size To 12,000 ft (3,660 m) 97⁄8 in. 75⁄8 in.

In laterals 61⁄8 in. 41⁄2 in.

This particular well was drilled on a pad that also had an offsetting single-lateral well that needed stimulation. Therefore, the plan was to stimulate the bottom lateral of the ML and then rig over and stimulate the single-lateral well. While that well was being treated, the diverters on the ML were switched simultaneously. Once the single-lateral offset well was completed, the pumping crews would switch back to treat the upper lateral of the ML. This saved the operator mobilizing charges for the pumping crews and maximized potential savings on all three laterals, which were stimulated in the course of one week. Both laterals were completed using five-stage openhole packer systems (Figure 1). Both laterals are now open and producing.

Results

The hanger system delivered two installed, stimulated, and producing laterals. The Frac-Point systems were run to total depth, and pressure integrity was maintained during all stimulation operations. The production results from the well met or exceeded expected results from offsetting wells. The cost savings were realized over drilling and completing two separate wells. The drilling cost proved to be 15% to 20% less, and the completion costs were nearly 50% cheaper than the average for stimulating two separate laterals. This reflects the cost savings captured by performing consecutive pumping operations on the pad without mobilizing and demobilizing pumping crews.

This well demonstrates the strong economic potential of ML completions in unconventional gas developments. Operators can save capital investment by accessing production from two laterals while drilling a single vertical well bore. Greater drainage access across a section is also possible by using this technology.

Maximizing production in the future

Hydraulically fractured ML gas wells have gained significant acceptance in the North American market, and the technology is moving into the international arena.

Baker Hughes completed a similar installation technique in Africa recently. The expected production result was 15 Mcf/d, but the production came in at 85 Mcf/d.

Although these results are not typical, it should not take long to gain acceptance on a global scale if success stories yield a five-times-greater production increase.

Currently, a North American gas well using two HOOK Hanger systems with three lateral legs is being completed and should realize an additional 15% to 20% savings over a single Hook Hanger deployment. Depending on the reservoir, as more lateral legs are added, the hydrocarbon recoverable factor significantly increases due to maximum reservoir exposure and more efficient well spacing and subsequent drainage.

Baker’s current pressure limit for ML equipment used in well fracturing is 10,000 psi. The future will easily push this limit, with formations being evaluated where the application of this technology could be 12,500 psi and possibly even 15,000 psi differentials.

Reservoir prediction models will have to be honed and improved to stay up with the results seen in the field. Well monitoring and intelligent production systems will begin to play a significant roll in multilateral completion techniques to maximize production, improve models to better understand reservoir drainage, and to minimize water production.

楊寶劍 是振威(全球)石油網的高級技術編輯,在石油技術資訊行業有八年的學識和經驗。他源源不斷地提供石油行業全球最新的技術創新、研發成果、現場應用情況等信息。如果你對“新技術新產品”的內容有任何問題或建議,請聯系楊寶劍編輯 +86 10-58236512 Email:allenyo@zhenweiexpo.com 歡迎您提供手中的最新技術文章!